GMT Mirror Actuators

Introduction

The Giant Magellan Telescope has seven mirrors, with an eighth mirror on standby. Each mirror requires about 160 actuators to maintain its shape under the load of its own weight. Some actuators have three air cylinders to move in the X, Y, and Z directions, and some have one cylinder to move in the Z direction.

From 2019 to 2021, our lab tested the design of the actuators and assembled and tested 160 actuators that were installed in a primary mirror test cell at the University of Arizona. The test cell was a stand-in for a real mirror so that the control system of the actuators could be tested.

Nearly all of the assembly and testing was performed by students, supervised by lab staff and a GMTO engineer. The assembly and testing procedures were designed by lab staff and approved by GMTO engineers.

Design Verification

The design of the actuator and control system was tested using several test stands and test procedures.

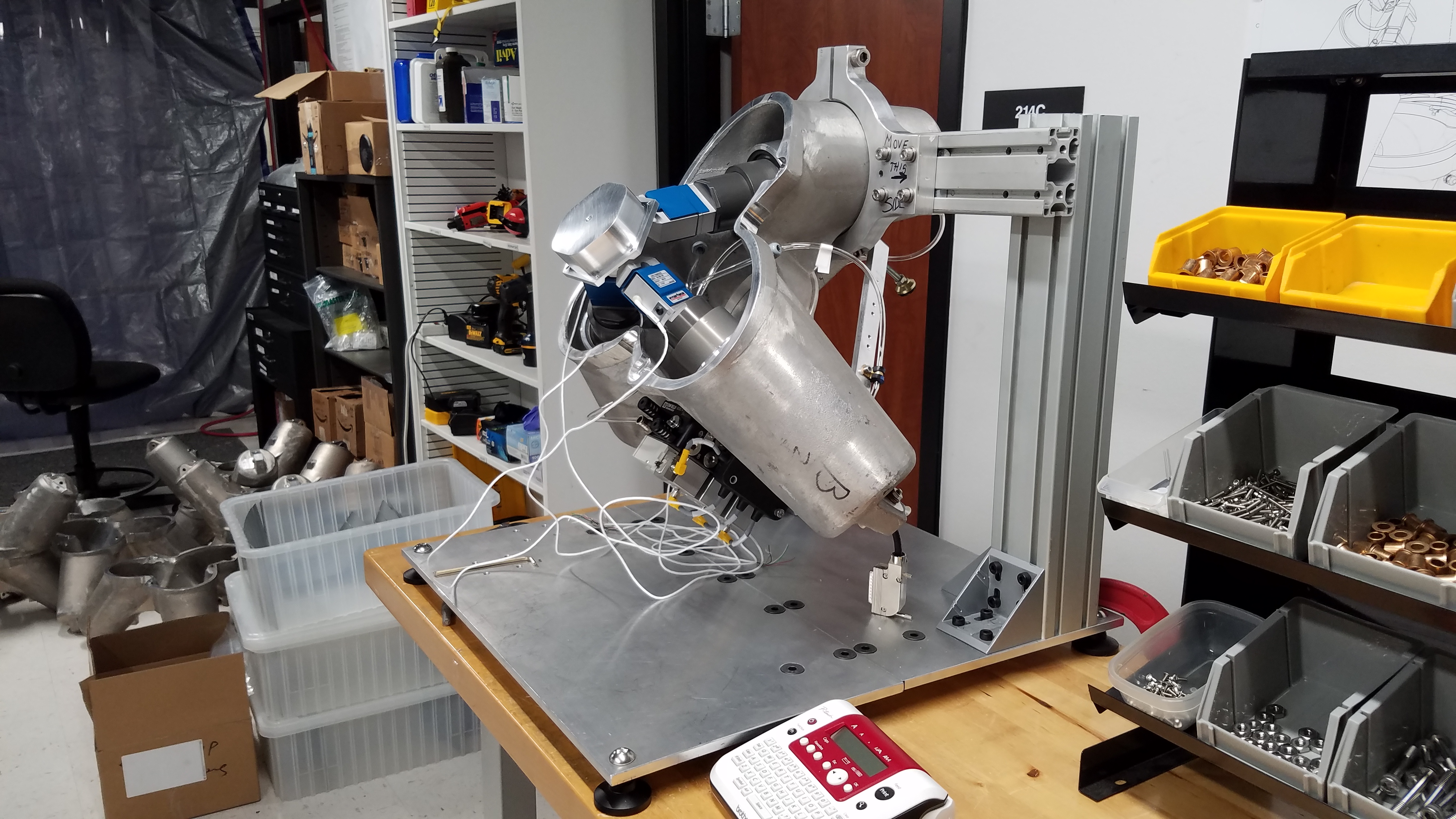

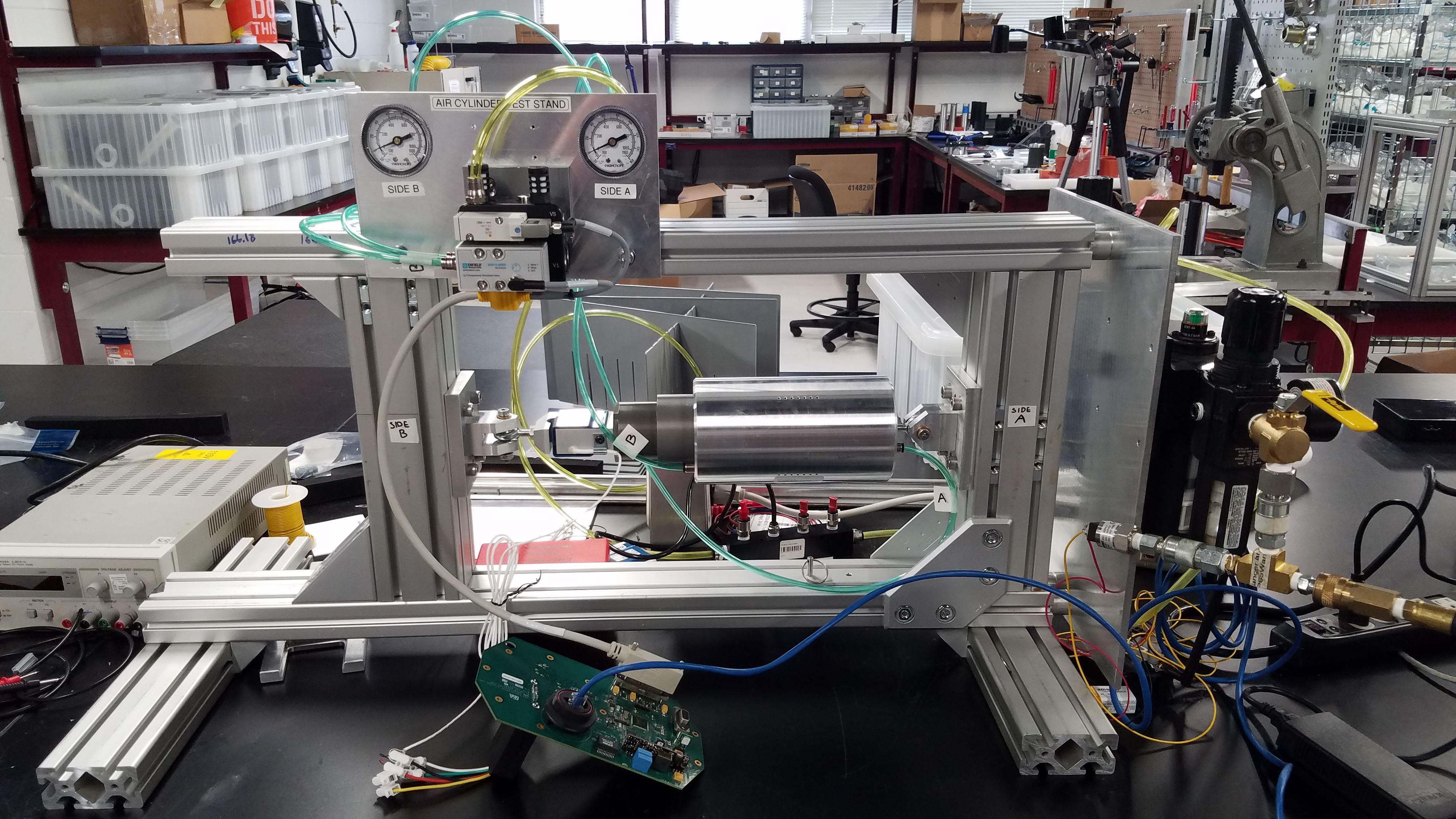

Life Cycle Test

One air cylinder was attached to an electric actuator, which pushed and pulled the air cylinder 200,000 times. This proved the air cylinder design could endure the life time of stresses on the GMT telescope. It was performed on one air cylinder that was not used for the final assembly.

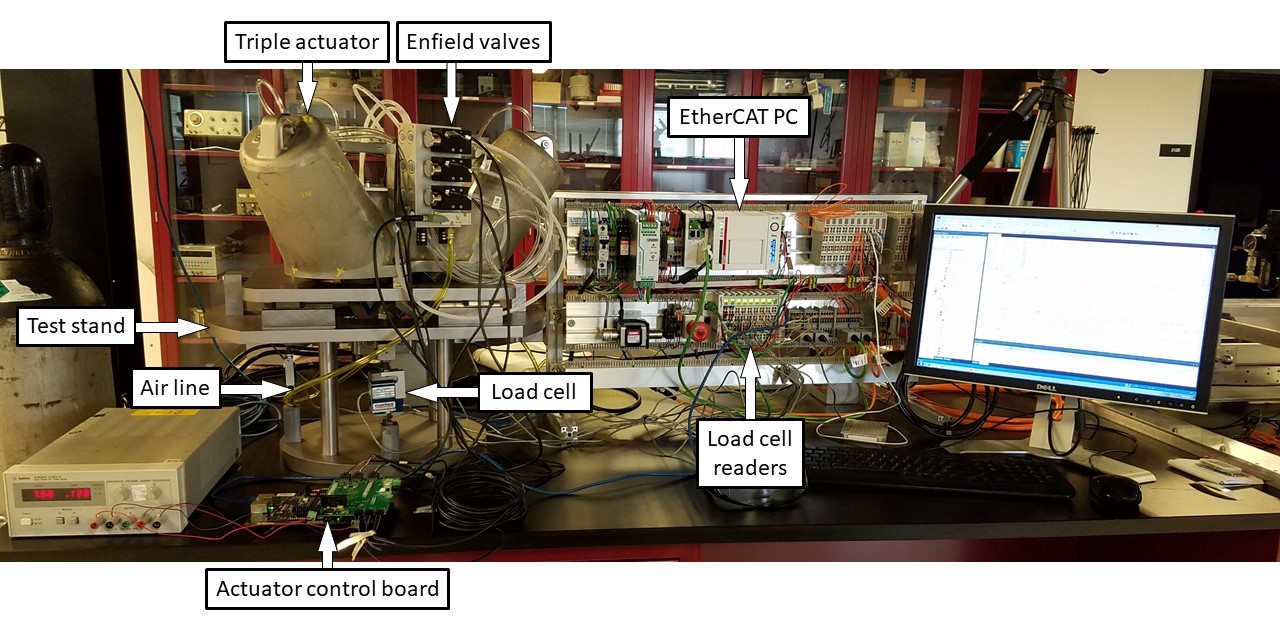

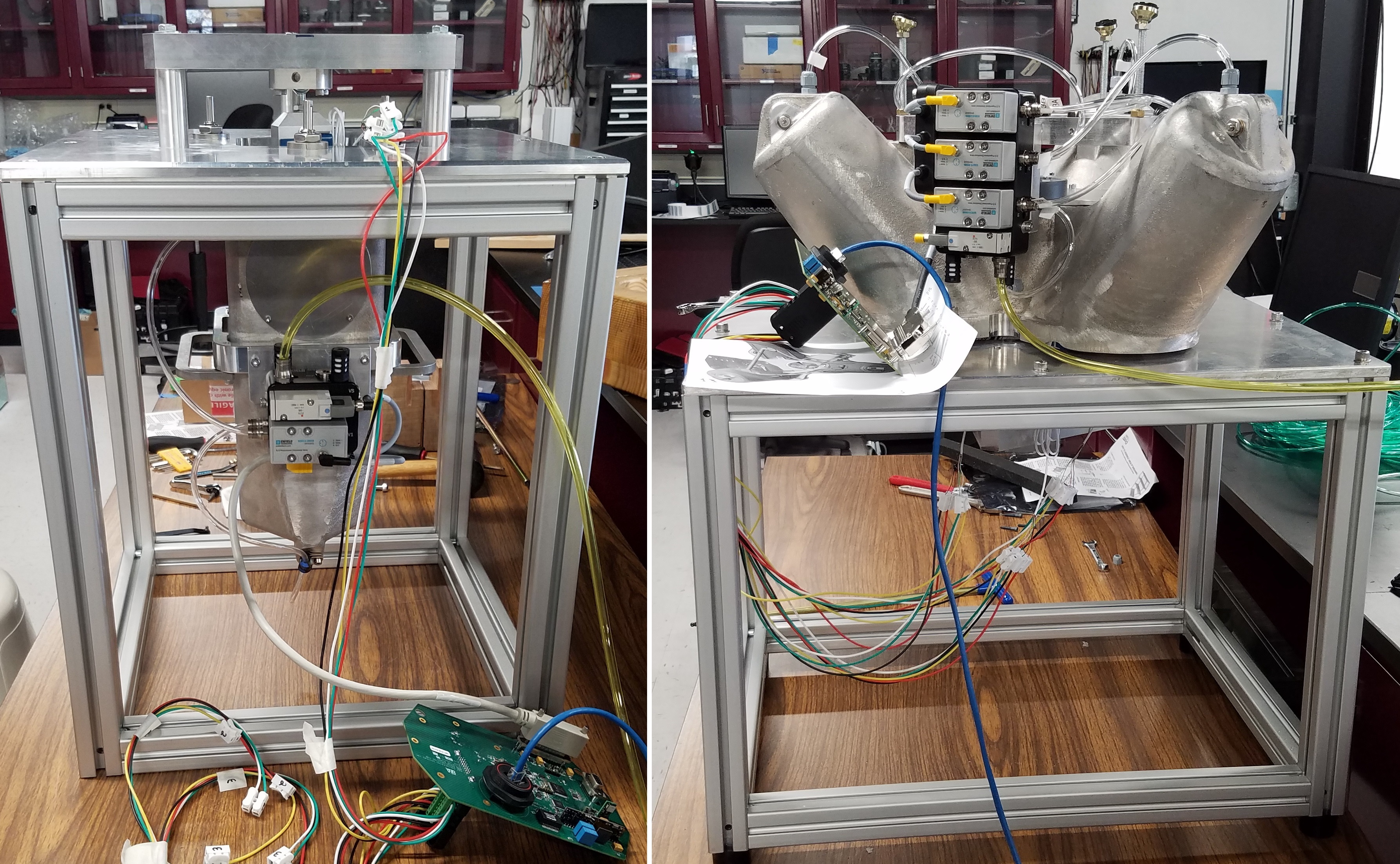

Triple Actuator Design Test

A test stand with three load cells in the X, Y, and Z directions verified that the intended force was being applied by the triple actuator design.

Air Cylinder and Actuator Assembly

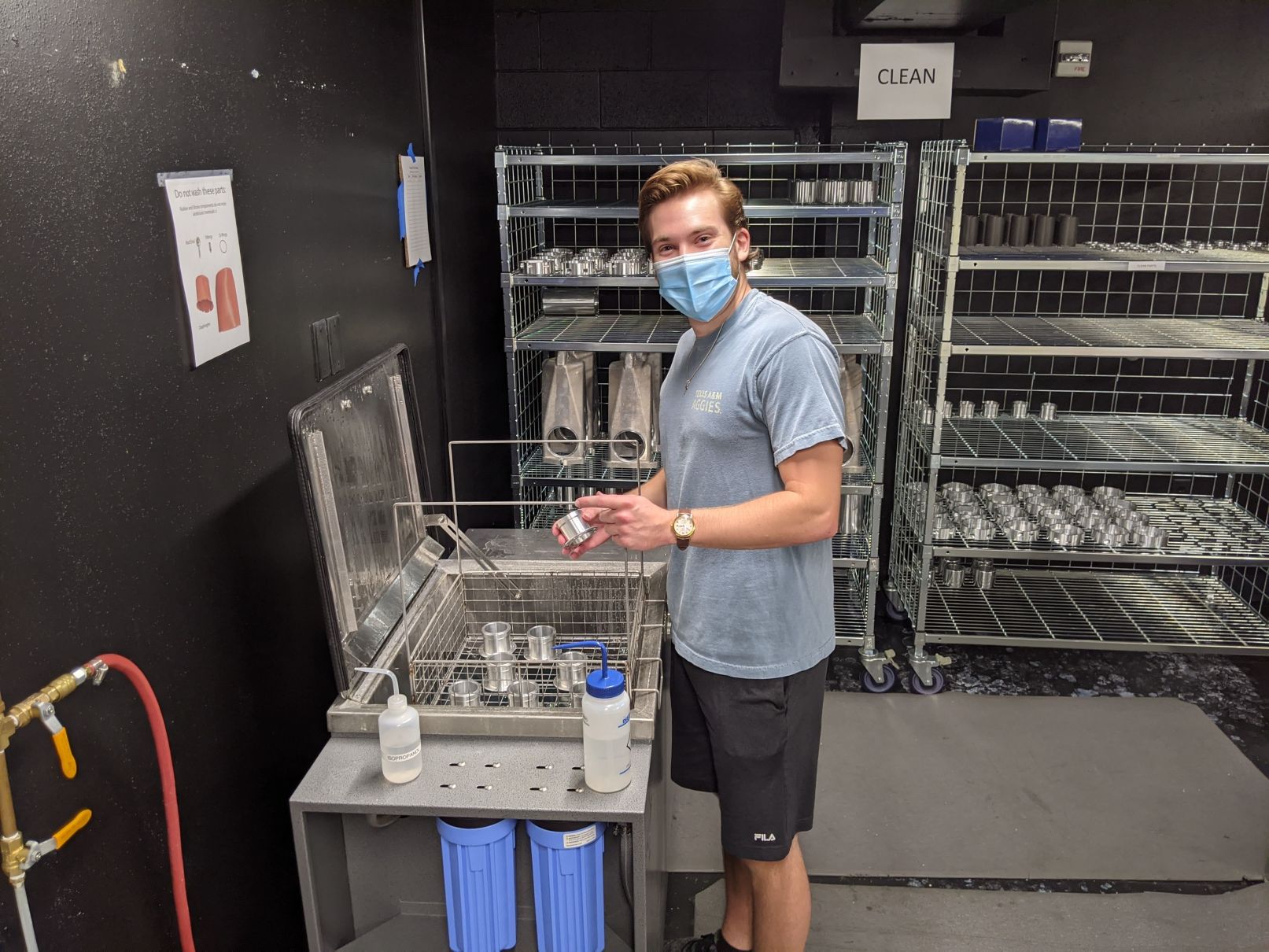

Parts arrived from various machine shops and needed to be cleaned to remove any residual metal shavings or oil residue. Industrial ultrasonic cleaners were used for the initial cleaning. Parts were then rinsed with distilled water and Isopropyl alcohol.

Machined parts and all required hardware were collected into kits to ensure all parts are available before assembly starts, and also to allow for verification that no parts were left out during assembly.

Individual air cylinders were configured for either a single or triple actuator (addition of load cell and mounting hardware, rod end distances are set) and then the air cylinders were assembled into actuator castings. Completed actuators were tested for functionality.

Testing

Each air cylinder, single actuator, and triple actuator was tested in a variety of test stands. Tests were conducted by lab staff and by students that were supervised by lab staff. The test procedures were approved by GMTO engineers.

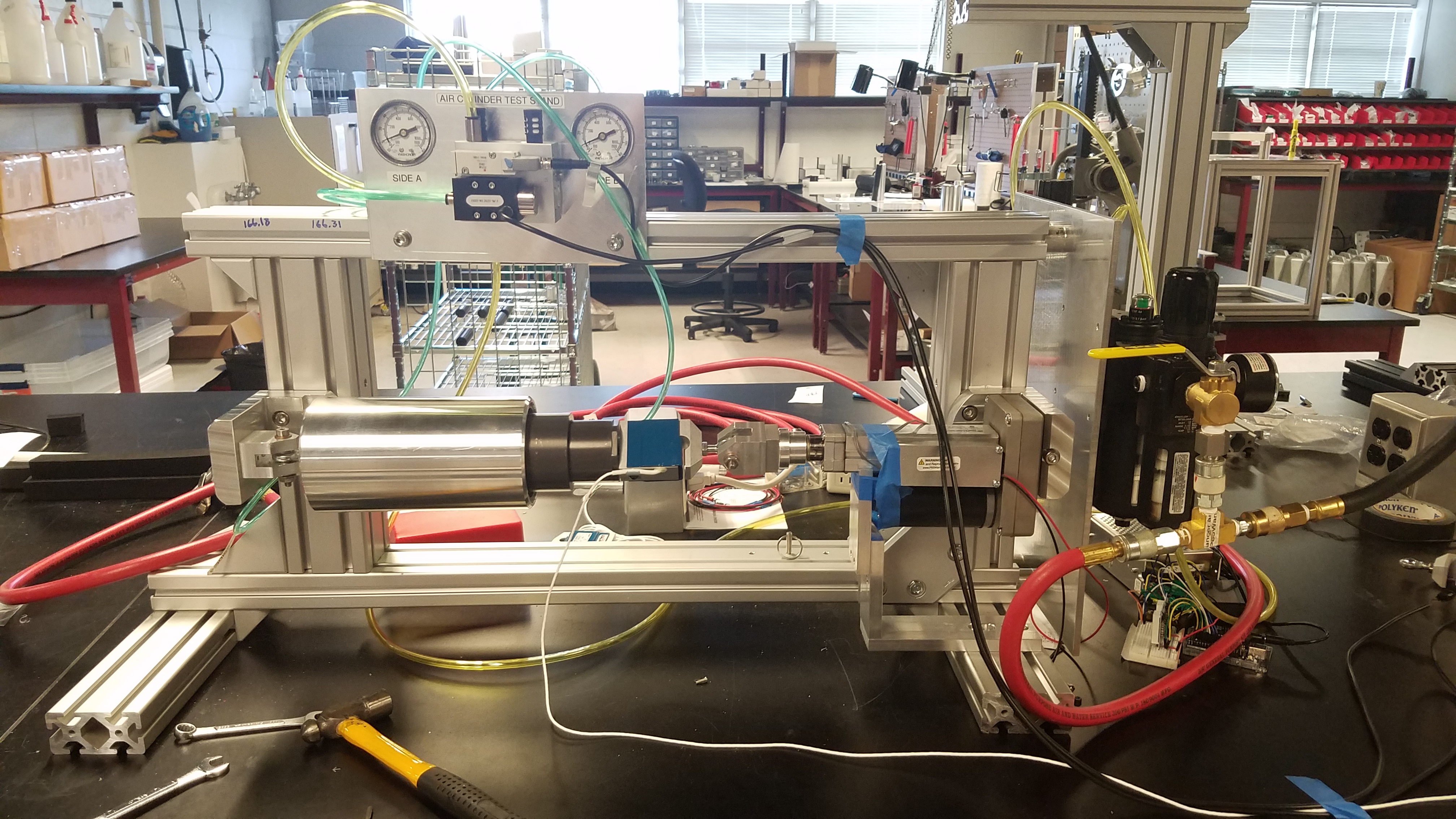

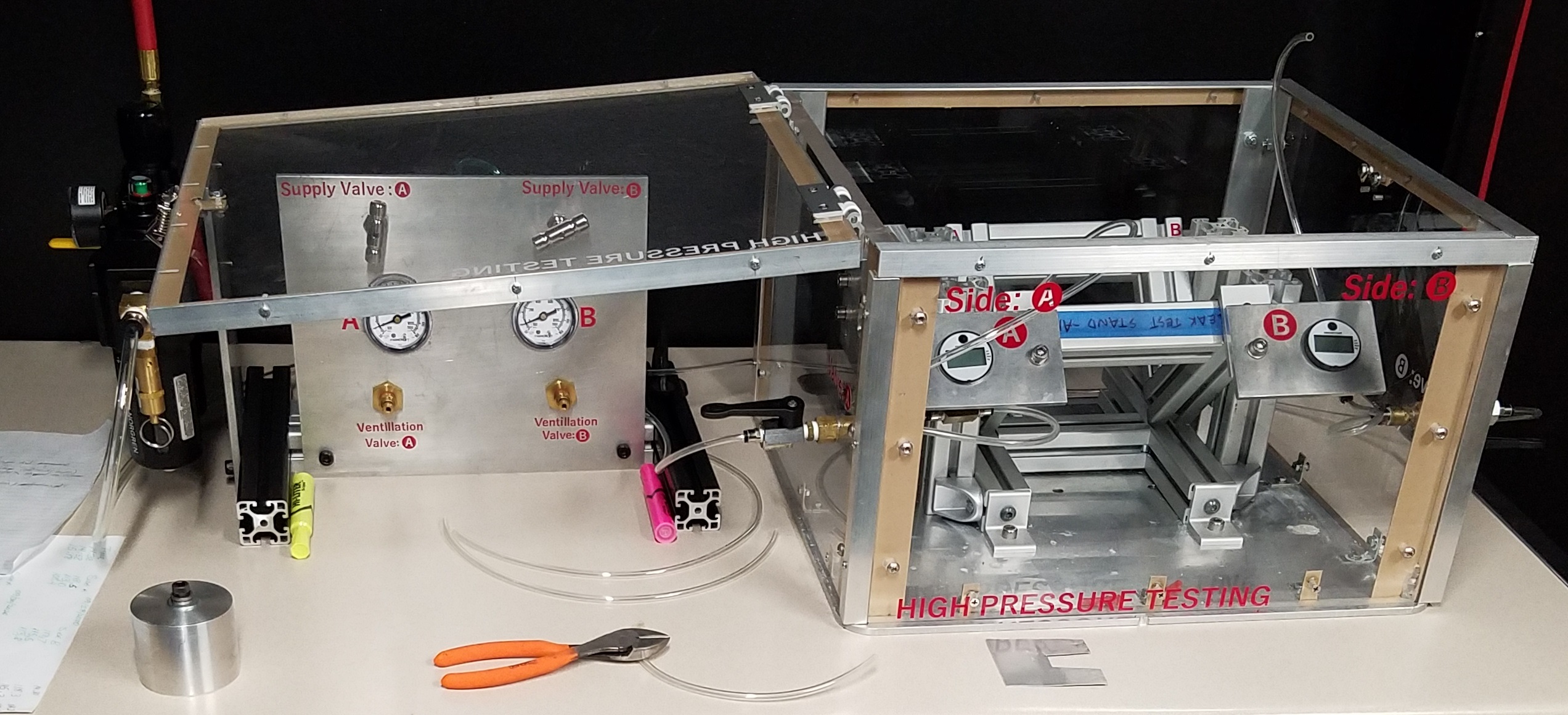

Air Cylinder High Pressure Test

Each air cylinder underwent a functional test to verify that it is able to apply and maintain the required forces. Cylinders were also tested for air leakage by pressurizing to 120PSI, isolating the cylinder with valves, and tracking the pressure drop over 20-40 minutes.

Air Cylinder Functionality Test

Valve Manifold Test

Each valve manifold was tested to detect internal leaks. The manifolds were attached to a test cylinder and load cell, and the force on the load cell was monitored to detect loss of pressure.

Actuator Functionality Test

Shipment

The actuators were packaged for shipping in custom shipping boxes with a folder of test data for each enclosed actuator. Each box contained either two single actuators, or one triple actuator. Boxes were shipped either 4 or 8 to a standard 4’x4’ pallet.