B&C Spectrograph Refurbishment

Undergraduate project: Jacob Stow, Tynan Weber

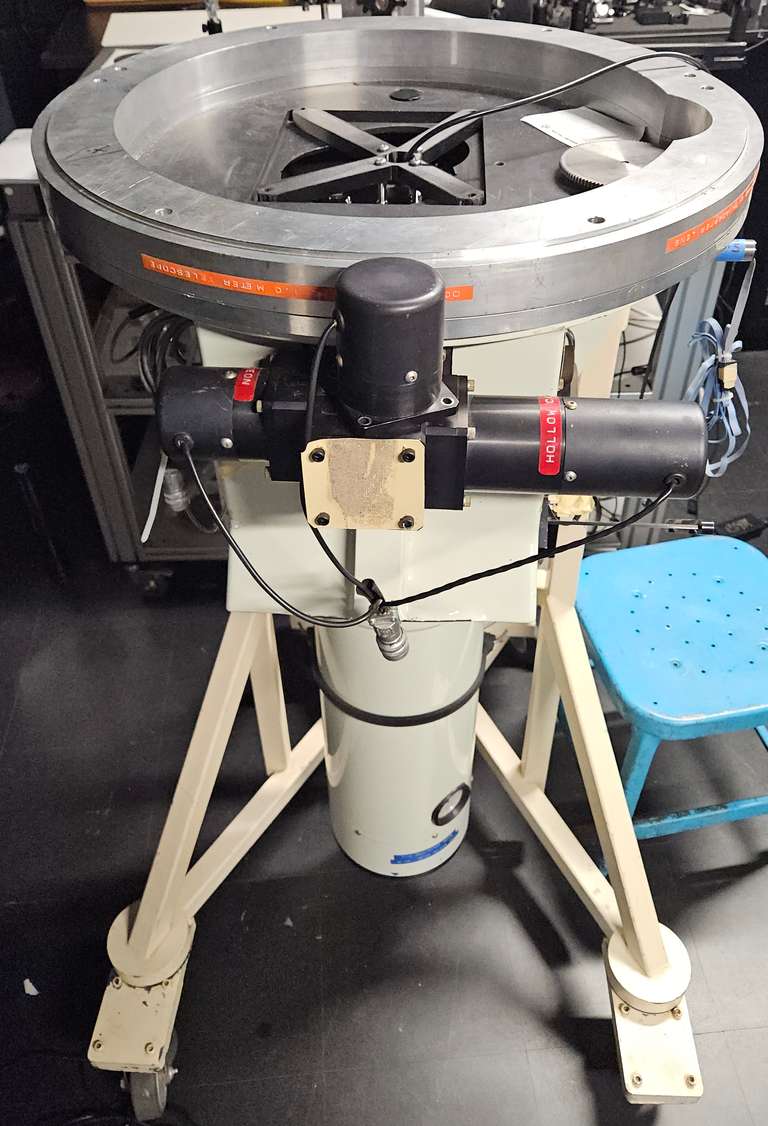

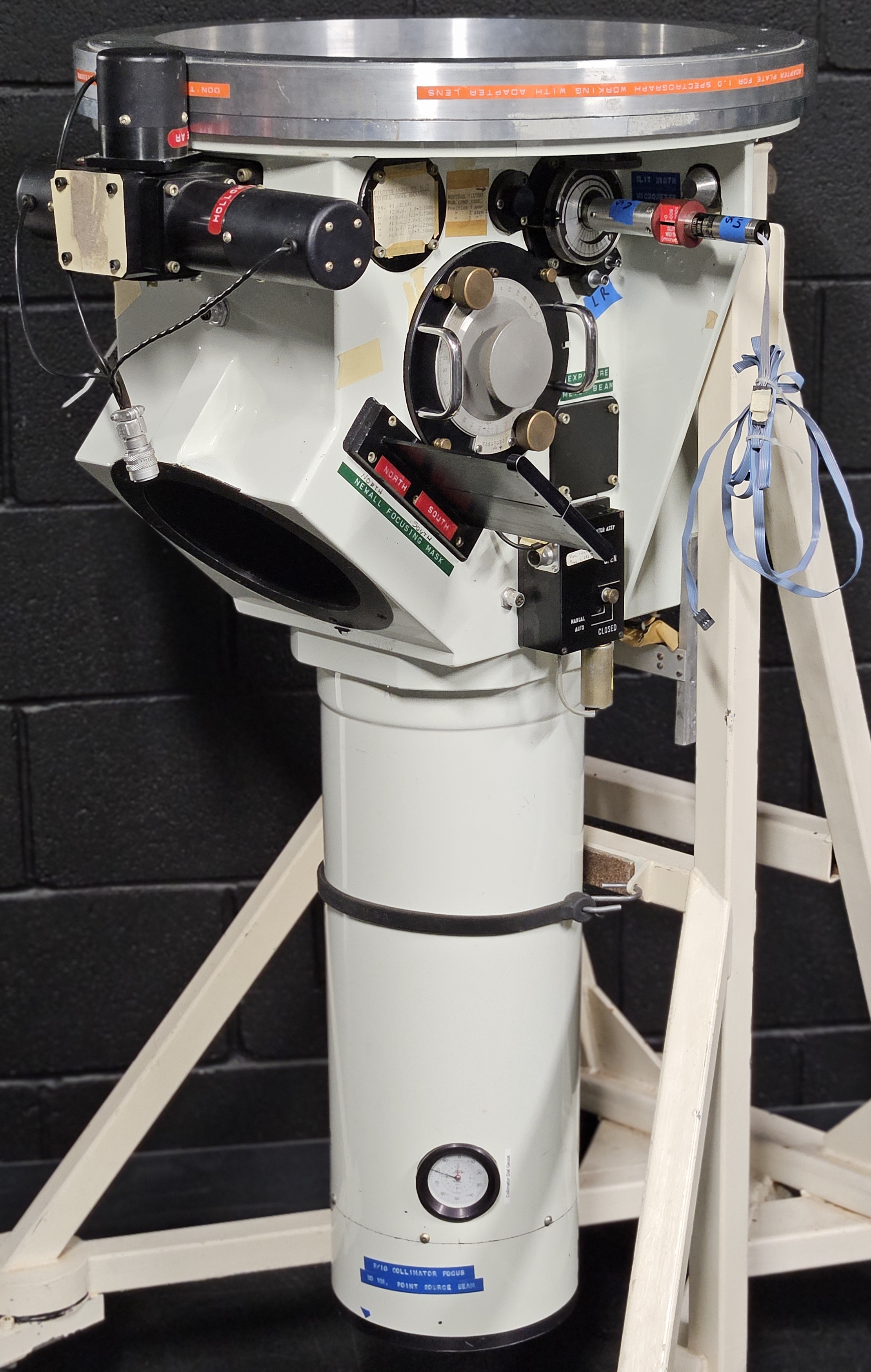

Our lab houses a Boller & Chivens (B&C) Cassegrain spectrograph model 31523 that was installed at the Cerro Tololo Inter-American Observatory (CTIO) in 1975. We are refurbishing it with modern controls and mechanisms.

The B&C Cassegrain Spectrograph Model 3153

The spectrograph manual provided to Observatorio Astronomico Di Brera by Boller & Chivens for the same model of spectrograph provides an overview of the instrument: "Light passes from the telescope through the slit and is collimated by an off-axis parabolic mirror. The collimated light is dispersed by a diffraction grating and is then reimaged by the camera onto the photographic plate. Other features include a decker, filter holder, provisions for an exposure meter, shutter, comparison light system, a 14 cm direct photography camera, and a 45 cm direct photography camera."

Refurbishment Plan

The spectrograph can be modernized by adding motor control for the slit width, collimator focus, and grating angle, as well as automated order blocking filters. The calibration lamps are replaced with new lamps and a new control system. Some subsystems are removed altogether because they are superseded by modern instrumentation, such as the exposure timer being removed because modern CCD and CMOS detectors have their own exposure controls.

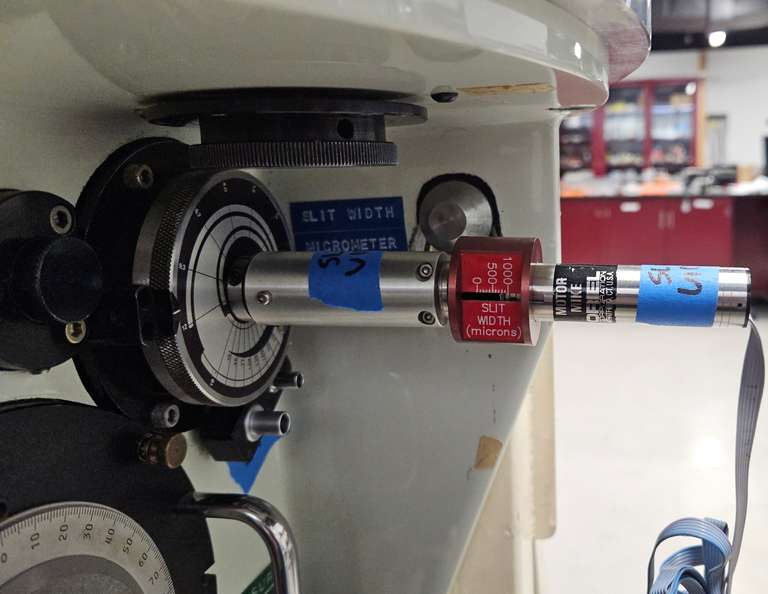

Slit Width

The first place light passes through to enter the spectrograph is the slit. The width of the slit is adjusted to change the spectral resolution of the spectrum. A narrower slit results in a higher resolution, but also less throughput, therefore, observers need to have control over the width of the slit during observations. Replacing the motor and control of the slit width allows observers to control the slit width through the instrument control software. The slit can also be set to a fixed width, eliminating the need for motor control.

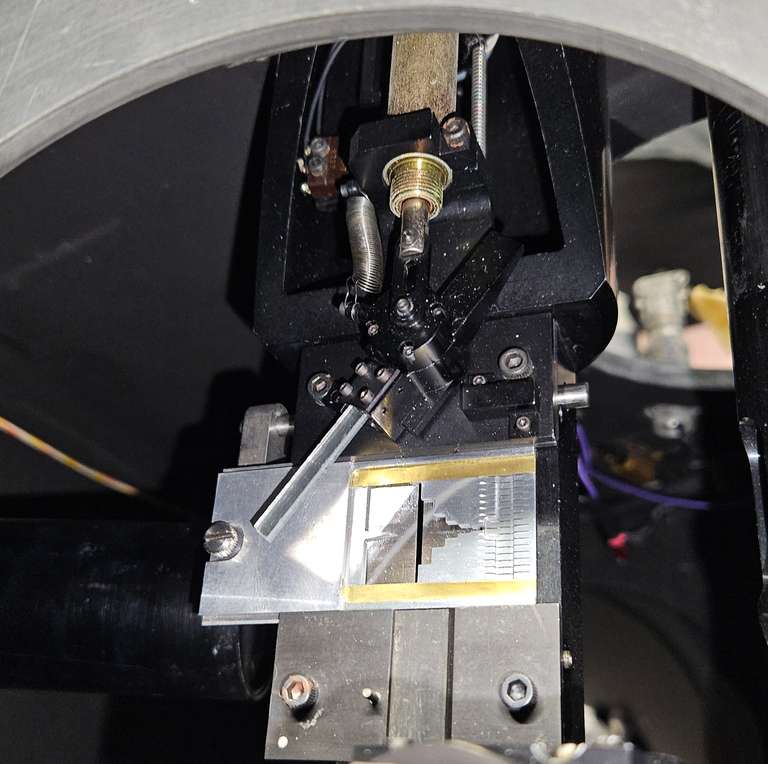

Collimator Focus

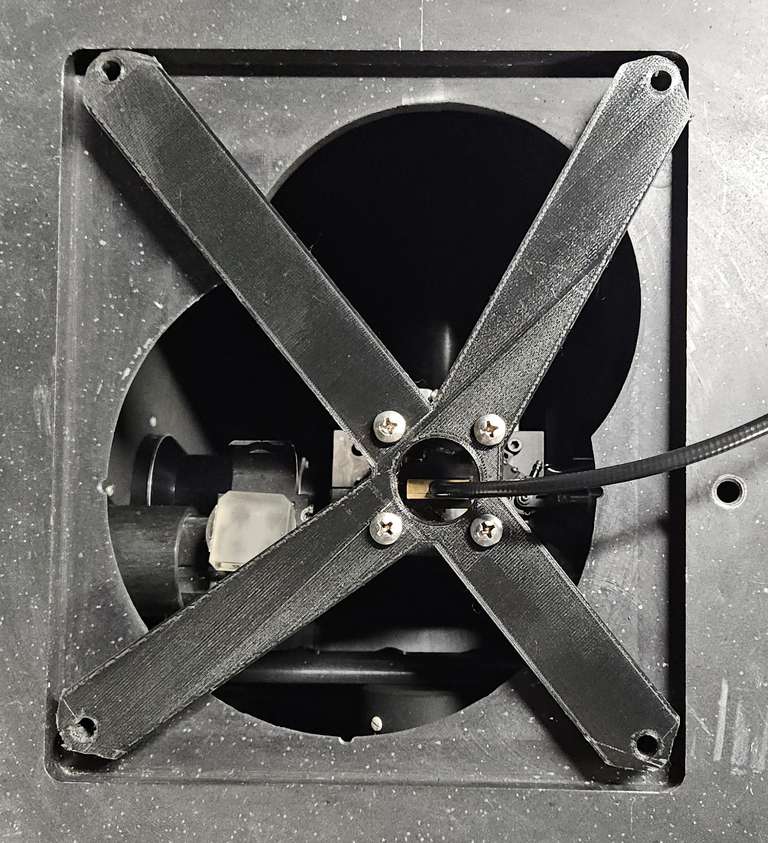

Just like images, spectra need to be focused. To focus the instrument, the collimator was designed to be adjusted by hand with a knob at the lower end of the spectrograph. Changing to a motorized adjustment allows users to control the focus using the control software. The collimator assembly is removed to add a motor to the mechanism.

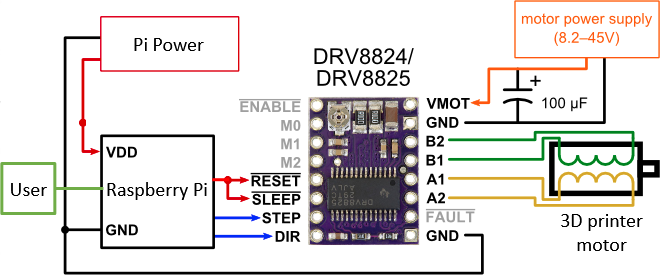

The motor is a 57mm NEMA 23 Stepper motor, reused from an old 3D printer. The motor is connected to the focus mechanism by an RC-018 set screw shaft coupling and driven by a DRV8825 motor driver carrier that receives commands from a Raspberry Pi.

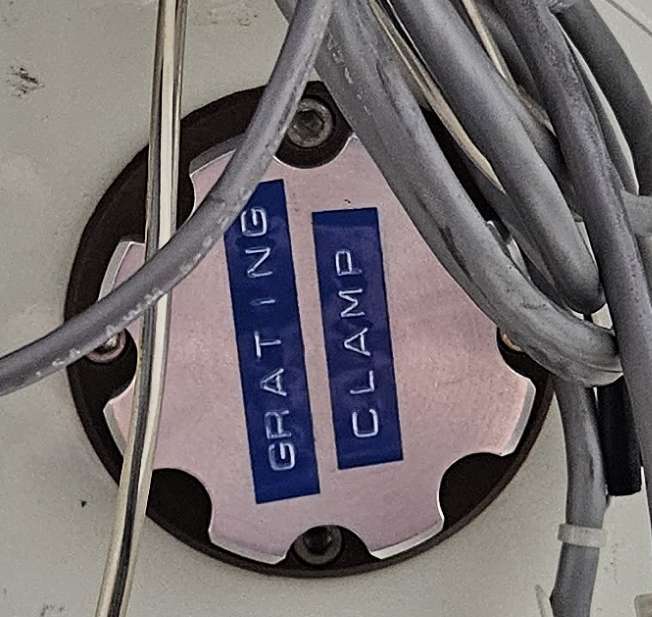

Grating Rotation

Reflective gratings disperse light into spectra, and the wavelengths of the spectra that land on the detector are control by rotating the grating. The hand-turned knob remains unmotorized, to be turned by the user for each acquisition.

Detector

For testing in the lab, an APOGEE Alta F15M with a 500mm lens gathers the light from the spectrograph output. A mount on top of the spectrograph shines light from a fiber bundle through the slit.